Provide Hengcai OEM program, product name and other information. The content of this information is for reference only.

Welding technology is one of the core technologies in the production of hydraulic cylinders. Usually, the life and performance of hydraulic cylinders are directly related to the welding quality. Advanced welding technology and processes are used to ensure the welding quality of the cylinders.

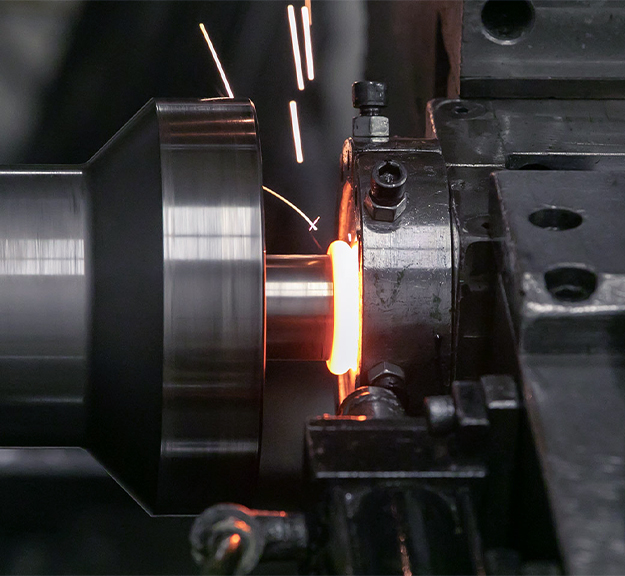

The heat treatment process is completed by an overall tempering device or a fully automatic surface induction heating device, followed by a hardness test, a tensile test and a fully automatic metallographic analysis test to ensure the heat treatment quality requirements.

The spraying is completed through a 315-meter fully automatic electrostatic coating production line or a large-scale manual coating production line. Test equipment for coating thickness, hardness, adhesion, corrosion resistance, etc. are used to ensure the quality of the spray.